Hay cutter used for cut green (dry) corn straw, straw and other crop straw and grass agricultural livestock machinery hay guillotine.

Working principle of grass cutter: it is powered by motor.The power will be transferred to the main shaft, the gear at the other end of the main shaft through the gear box, universal joint will pass through the speed of the power to the grass roller, when the material to be processed into the top and bottom of the grass roller, and at a certain speed into the cutter cutter mechanism, after high-speed rotation of the cutting tool through the grass mouth out of the machine.

Cattle feed chaff cutter

Hay cutter

Animal feed grass cutter

Hay cutter used for cut green (dry) corn straw, straw and other crop straw and grass agricultural livestock machinery hay guillotine.

Working principle of grass cutter: it is powered by motor.The power will be transferred to the main shaft, the gear at the other end of the main shaft through the gear box, universal joint will pass through the speed of the power to the grass roller, when the material to be processed into the top and bottom of the grass roller, and at a certain speed into the cutter cutter mechanism, after high-speed rotation of the cutting tool through the grass mouth out of the machine.

Hay cutter performance characteristics:

● steel frame, small size, light weight, easy to move.

● design safety device, eliminate the knife accident, the whole machine is safe and reliable.

● dry and fresh general hay cutter adopts advanced grass feeding mechanism, unique grass feeding roller device, automatic feeding, conveying chain not wrapped grass, grass feeding smooth, high productivity.Grass roller drive shaft with universal coupling, compact structure, flexible operation, easy to disassemble.

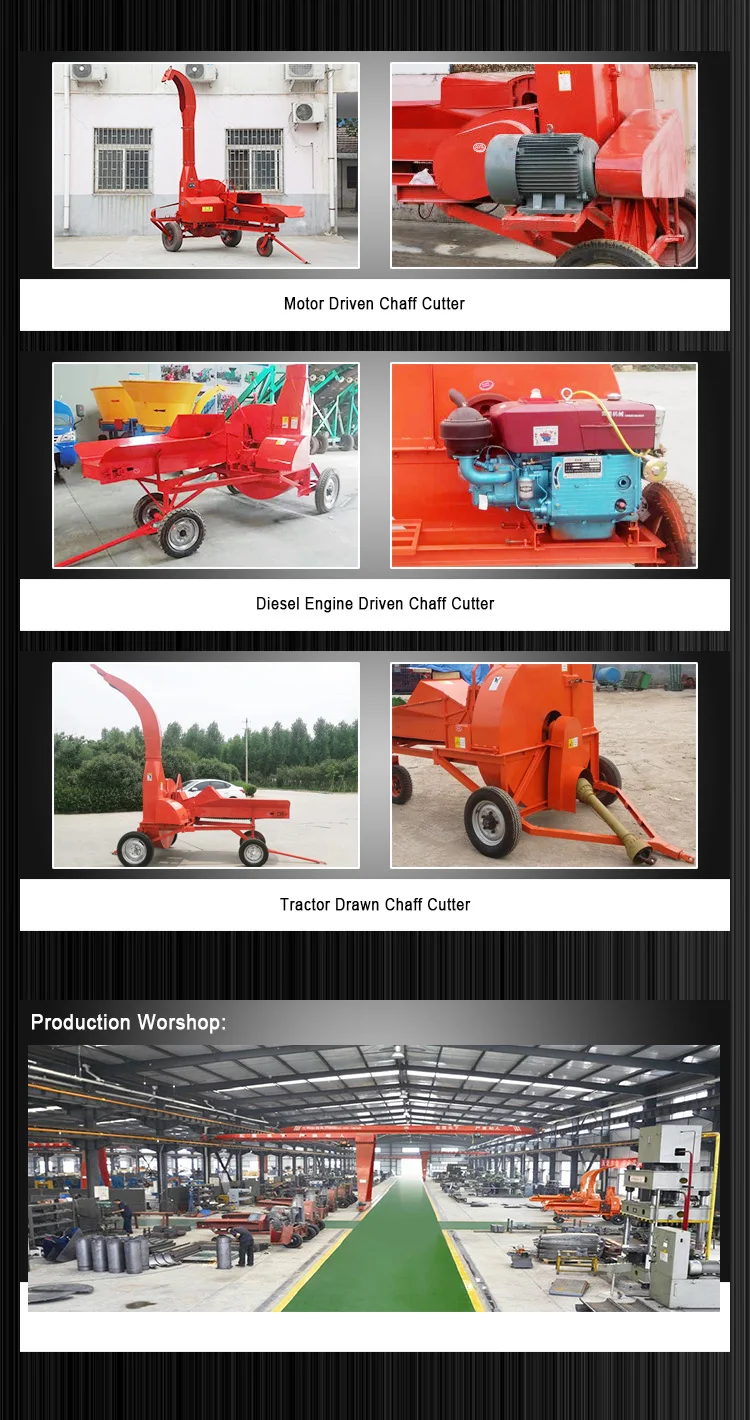

● supporting power options, motors, diesel engines, tractors can be supporting, especially for the lack of electricity more appropriate.

● the blade is made of high quality steel, which is refined by a special process.Adopt high strength bolt, safe and reliable.

● the machine shell is made of thickened steel plate welded continuously, the overall mold is formed, beautiful and generous, durable.

● cost-effective, the same productivity guillotine prices.

The cutter is mainly composed of feeding mechanism, cutting mechanism, throwing mechanism, driving mechanism, walking mechanism, protective device and frame.

Chaff cutter machine is suitable for large and medium-sized animal husbandry plant to be used for various dry and wet fresh crop straw and grass.

After processing, the forage grass is soft, without a round rod, no hard knot, and the livestock feed rate is high. It can also improve the uniformity of the mixing of forage grass and other fine feed, reduce waste, and reduce the feeding cost of livestock.

This model combines the main structure of cutter and forage mill, and solves the problem of high energy consumption and low efficiency of forage mill.

Excellent performance, reliable operation, safe operation.

Its components are as follows:

1) feeding mechanism: mainly consists of feeding platform, up and down cao, fixed blade and fixed knife support base.

Ensilage machine

2) guillotine throwing mechanism: mainly consists of dynamic knife, cutter plate, locking screw and so on.

3) transmission mechanism: mainly composed of triangle belt, transmission shaft, gear, universal joint, etc.

4) walking mechanism: mainly consists of ground casters.

5) protective device: consists of a protective cover.

| Model | NKCC-0.4 | NKCC-1.5 | NKCC-3.0 | NKCC-5.0 | NKCC-8.0 | NKCC-10.0 | NKCC-12.0 | NKCC-30.0 |

| Capacity(t/h) | 0.4-1 | 1.5-2.5 | 2.5-3.5 | 4.5-5.5 | 6-8 | 8-10 | 12-15 | 30 |

| Power(Kw) | 2.2 | 3 | 4 | 5.5 | 7.5 | 15 | 18.5 | 30 |

| Rotary Speed(r/m) | 2800 | 2800 | 1440 | 1440 | 1440 | 1440 | 1470 | 1470 |

| Blade Rotary Speed(r/m) | 1050 | 1050 | 800 | 800 | 650 | 500 | 500 | 450 |

| Blades(pcs) | 4/6 | 3/4 | 2/3/4 | 4 | 3/4 | 3 | 3 | 3 |

| Belt Qty(pcs) | 2*B1550 | 2*B1550 | 3*B1650 | 3*B1800 | 3*B2150 | 5*B3000 | 5*B2900 | 3*C3050 |

| Cutting Length(mm) | 12-35 | |||||||

| Output Air Conveying Distance(m) | 1-5 | 1-5 | 1-5 | 4-6 | 5-8 | 10-15 | 10-15 | 10-15 |

| Weight(kg) | 60 | 90 | 138 | 280 | 400 | 880 | 1000 | 2300 |

| Total Size(mm) | 650*500

*600 |

820*460

*1160 |

1230*1150

*1695 |

1737*1575

*2315 |

2147*1600

*2756 |

2620*2140

*4110 |

2630*2230

*4120 |

4290*2510

*4510 |

| Delivery Size(mm) | 510*952

*1050 |

630*1010

*1300 |

1755*1393

*1585 |

2620*1720

*1850 |

2630*1690

*1870 |

3630*2070

*2810 |

||

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.